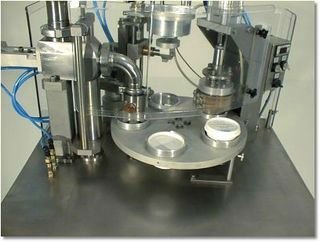

Yogurt Making Machine

Yogurt Making Machine Specification

- Product Type

- Yogurt Making Machine

- General Use

- Industrial Yogurt Production

- Material

- Stainless Steel 304/316L

- Type

- Fully Automatic

- Capacity

- 500L-2000L per batch

- Weight (kg)

- 1200 kg (approx.)

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Processing Pressure

- 0.2-0.4 Mpa

- Cleaning System

- CIP (Clean-In-Place)

- Cooling Mode

- Automatic Chilling System

- Sterilization Method

- Pasteurization

- Motor Power

- 4.5 kW

- Voltage

- 380V / 50Hz (Customizable)

- Dimension (L*W*H)

- 2200*1100*1850 mm (approx.)

- Feature

- Energy-Efficient, Corrosion Resistant, Easy Installation

- Color

- Silver

- Ambient Temperature Range

- 5C-40C

- Sanitary Standards

- Meets Food Grade Requirements

- Mixing Speed

- 36 rpm (Customizable)

- After-sales Service

- Online Support, Field Installation, Commissioning and Training

- Insulation Layer

- Polyurethane Foam

- Inner Tank Polishing

- Mirror Polish Ra 0.4um

- Noise Level

- <70 dB

- Heating Method

- Electric/Steam Heating

- Application

- Milk, Soy Milk, Yogurt fermentation

About Yogurt Making Machine

Yogurt Making Machine

Precision Engineering for Consistent Fermentation

The highly polished inner tank and PLC-controlled process guarantee consistent yogurt quality batch after batch. Automated functions streamline production, minimize human oversight, and help maintain optimal hygienic standards. This reliable system supports dairy producers seeking to scale up with confidence and deliver premium products to market.

Efficient Energy Use and Sanitary Design

Equipped with energy-efficient motors and a polyurethane foam insulation layer, this machine minimizes operational costs while maintaining strict temperature control. The corrosion-resistant stainless steel construction extends machine life, and the inbuilt CIP system provides hassle-free cleaning, making compliance with food grade standards effortless.

FAQ's of Yogurt Making Machine:

Q: How is yogurt fermentation controlled in this machine?

A: Yogurt fermentation is precisely regulated through a computerized PLC control system, which allows operators to set and monitor temperature, mixing speed, and processing time. This automated process maintains ideal conditions for dairy and soy milk fermentation, ensuring consistent results every batch.Q: What materials are used in the construction of the inner tank, and why are they beneficial?

A: The inner tank is constructed from food-grade stainless steel (304/316L) with a mirror polish of Ra 0.4um. This ensures resistance to corrosion, facilitates easy cleaning, and helps maintain hygienic conditions crucial for industrial yogurt production.Q: When is the best ambient temperature range for using this yogurt making machine?

A: The machine operates optimally within an ambient temperature range of 5C to 40C, making it suitable for diverse production environments without compromising on performance or safety.Q: Where can installation and training support be accessed for this machine?

A: After-sales support includes both online assistance and field services such as installation, commissioning, and user training. These comprehensive support options are available to customers in India and internationally.Q: What processes are included in each batch of yogurt production?

A: Each batch involves pasteurizing the raw milk or soy milk, followed by controlled fermentation in the tank, automatic cooling to achieve the desired consistency, and cleaning via the integrated CIP (Clean-In-Place) system. All steps are managed by the machine's automated controls.Q: How does the machine benefit large-scale yogurt producers?

A: Large-scale producers benefit from the machine's high batch capacity (500L-2000L), fast processing speed, energy-efficient operation, strict food safety compliance, and reduced labor requirements thanks to its fully automatic features and computerized monitoring.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dairy Products Machinery Category

Milk Atm Machine

Price 200000 / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Stainless Steel (SS304)

Voltage : 220V/50Hz, Single Phase

Type : Other, Automatic Vending/Dispensing Machine

Automatic Milk Pasteurization Plant

Price 1200000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Voltage : 450 Volt (v)

Type : Milk Pasteurization Plant

Drive Type : Electric

Mini Milk Plant

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Voltage : 450 Volt (v)

Type : Milk Plant

Drive Type : Electric

UHT Milk Processing Plant

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Voltage : 450 Volt (v)

Type : Milk Processing Plant

Drive Type : Electric

Send Inquiry

Send Inquiry